BIOMASS

This BB Bulls is a leading biofuel Company for the biomass briquetting community, Pellets, Coffeehusks, sawdust, Woodchips and the biomass power community at large. It caters to the needs of all stakeholders i.e. manufacturers, suppliers, and buyers, who would be biomass entrepreneurs in a biomass energy cycle

What is Briquette?

A Briquette (or briquet ) is a compressed block of combustible biomass material such as sawdust, bagasse, wood chips, etc. used for fuel in boilers and other heating applications. The term comes from the French language and is related to bricks.

Biomass Briquette Systems specializes in briquette presses, grinders, granulators, augers, and silos that are used in the biomass industry.

Biomass Briquette Systems grinders and briquetting presses are capable of densifying wood waste and many other agricultural feedstocks containing less than 15% moisture. These feedstocks can easily be ground and pressed into a high-value solid fuel briquette that can then be used for heating and energy applications.

Benefits of Biomass

The use of biomass energy has various benefits and those are mostly environmental and economic

- No harmful emissions

- Clean Energy

- Abundant & Renewable

- Reduce dependency on Fossil Fuels

- Reduce landfills

- Can be used to create different products

Use of Briquettes

Biomass Briquettes can be used by the industrial, commercial and household sectors such as:

1. FMCG & Beverages Industry

2. Pharmaceuticals Industry

3. Brick Kilns

4. Dyeing Plants

5. Honey Extraction Plants

6. Milk Plants

7. Food Processing units

8. Oil Extraction Units

9. Cooking & Baking

10. Cement Plants

11. Leather Industry

12. Paper Mills

13. Rubber Industry

14. Chemical Plants

15. Residential heating & many more

We purchased raw materials directly through farms So they get real value for what they need. We support farmers. We support their happy smile!

What We Do As Briquette Manufacturers?

We supply various types of Biomass Briquettes to Industries

- Production of Biomass Briquetts to Industries

- Supply Chain Management

- Provider of Equipments

- Biomass Assessment & Technical consultation

Shape | Cylindrical |

Size (in Diameter) | 70/90/100 mm |

Length | 20 – 300 mm |

Calorific Value | 3800+ Kcal/Kg |

Ash Content | Less than 10% |

Density | 1.2 t/m3 |

Pellets - Definition & Properties

A wood pellet with or without additives is a compressed feedstock material, normally cylindrical with broken ends, with a length of typically 5mm to 40mm and a diameter of maximum 25mm. The moisture content of wood pellets normally is less than 10% and they have an ash content of up to 3%. The pellets usually were produced with a pellet mill.

The advantages of pellets compared to log wood orwood chips are among others: the possibility to optimize the combustion because of the uniform fuel, the reduced costs for transportation because of the increased fuel bulk density and the improvement of thermal and combustion properties.

Application of Pellet Stoves / Boilers

Pellet stoves are free-standing devices with or without a viewing window, which are using pellets as fuel. A pellet boiler also provides hot water.

The conditions while burning pellets are much more constant than while burning logwood, because of the homogeneity of the pellets. Therefore pellet-fired units operate more efficiently and have reduced emission rates, as compared to logwood or wood chip units. Another big advantage of pellet stoves/boilers is the possibility of automated fuel feeding. Integrated storage hoppers for pellets even enable automatic operation for several days. The pellets are, for example, transported by a fuel screw into the combustion chamber and usually ignite automatically with a glow plug. Therefore pellet-fired units need electricity during the operation.

Pellet stoves and boilers can be equipped with smart technology, like flue gas sensors, to improve their performance. Pellet-fired units currently are the state-of-the-art solution for biomass combustion.

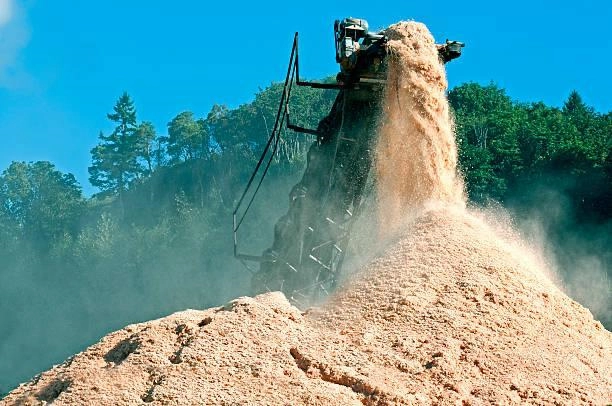

Production Process

Pellets are produced by compaction of e.g. saw dust. For detailed information see pre-treatment technologies.

Raw Materials

The common pellets are made from woody biomass, like sawdust, wood chips or forest residues, but there are a variety of raw materials which can be pelletized. Some examples are paper products, waste biomass, corn, cotton seed, hemp, miscanthus, reed canary grass, straw, cereal spillage, low grade hay etc.. The fuel properties of pellets made from alternative raw materials differ from pellets made from woody biomass. For example: The water content of wood pellets amounts to maximum 15%, otherwise they will fall apart. In contrast, the water content of alternative pellets varies between 7% (corn cobs) and 56% (hemp). Certain fuel properties can be set by mixing different raw materials together in suitable amounts.